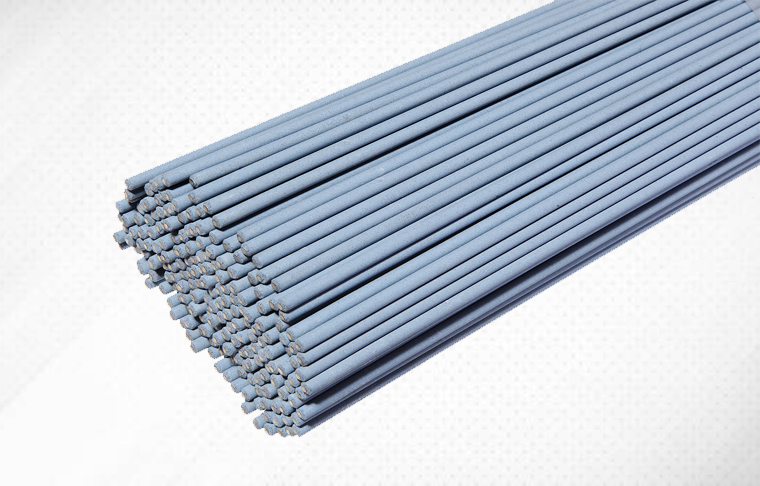

Rutile Electrodes

This electrode can really be used universally. It can be used in

any position and with many different applications. It provides

an exceptional self-assurance for welders. Good weld bead

appearance. Easy slag removal.

Applications

Metal structures in general, sheet metal, piping, metal works,

containers, tanks, boilers, handicrafts, ironmongery, etc...

Advantages :

- Universal all positions

- Excellent handling

- Smooth and stable arc

- Self-releasing slag

|

Typical Weld Metal Composition (%):

|

Fe:

(base)

|

C:

<0,10 |

Mn:

0,6 |

Si:

0,4 |

S:

<0,025 |

P:

<0,025 |

|

All Weld Metal Mechanical Properties:

|

Rp 0,2: > 400 MPa

Rm: 510-580 MPa

A5:

> 22 %

|

|

Electrode polarity:

|

Negative |

|

Output Circuit Voltage (OCV):

|

∼ 40 V |

Basic Electrodes with High Weldability

Basic coated electrode presenting exceptional welding

characteristics due to its double coating. Arc very stable.

Almost spatter-free. Easy removal of the slag. Recommended for

root passes and on badly prepared joints.

Applications :

Frames, heavy supports, shipbuilding, pressure vessels, metal

constructions and all repair works.

Advantages :

- Excellent handling for welders

- High resistance to cracking

- Smooth and stable arc

- Easy slag removal

Technical Data

|

Typical Weld Metal Composition (%):

|

Fe:

(base) |

C:

<0,10 |

Si:

0,7 |

Mn:

0,9 |

P:

0,02 |

S:

<0,02 |

|

All Weld Metal Mechanical Properties:

|

Re: 450 MPa

Rm: 550 MPa

A5: 27 %

|

| Electrode polarity: |

Positive |

| Output Circuit Voltage (OCV): |

∼ 70 V |

Stainless Steel 316l Rutile-Basic Electrodes

It is a Rutile-basic electrode, providing a weld metal in low

carbon austenitic stainless steel (316L). Used for welding of

18/8/3 austenitic stainless steels and cladded steels. It

provides excellent resistance to corrosion. Smooth welding. Easy

slag removal.

Applications

Chemical and petrochemical industries, shipbuilding, tanks,

pipes, heat exchangers, food industry.

Advantages

- Low carbon universal stainless steel

- Excellent corrosion resistance

- Excellent handling for welders

- Coating with very low moisture absorption

Technical Data

|

Typical Weld Metal Composition (%):

|

Fe:

(base)

|

C:

<0,03

|

Si:

0,8

|

Mn:

0,7

|

Cr:

18,5

|

Ni:

12 |

Mo:

2,7

|

|

All Weld Metal Mechanical Properties:

|

Rp 0,2: > 400 MPa

Rm: > 560 MPa

A5:

> 35%

|

|

Electrode polarity:

|

Positive |

|

Output Circuit Voltage (OCV):

|

∼ 70 V |

Stainless Steel 312 Rutile-Basic Electrodes

Rutile-basic electrode with an enhanced mechanical

characteristic of the deposit of stainless steel. Highly

resistant to cracking. Welding all low-alloy and high-alloy

steels. It is a multipurpose electrode for high security

repairs. Soft fusion, nice appearance of the beads, self

releasing slag.

Applications

Repairing and maintenance on dissimilar, difficult-to-weld or

unidentified steels. Suitable for buffer layers before hard

facing, building up piston rods, gears.

Advantages

- Ideally universal

- High resistance

- Stainless deposit

- Nice appearance of the weld beads

Technical Data

|

Typical Weld Metal Composition (%):

|

Fe:

(base) |

C:

<0,10 |

Si:

1,0 |

Mn:

0,6 |

Cr:

29,0 |

Ni:

9,5 |

Mo:

0,5

|

|

Mechanical characteristics of the deposit:

|

Rp 0,2: > 500 MPa

Rm: 750/850 MPa

A%:

> 20

|

| Electrode polarity: |

Positive |

| Output Circuit Voltage (OCV): |

∼ 50 V |

Nickel Pure Electrodes for Cast Iron

Graphite electrode with high percentage of nickel, for cold

repairing of different grades of cast iron. Very soft fusion.

High conductivity.

Applications

Repairing of engine blocks, frames of tool machines, gear

reducers, valve and pump bodies, cast parts.

Advantages

-

Excellent weldability in all positions, without preheating.

- Homogeneous and easy-machining deposit.

- Great deposit extension for lamellar cast iron.

- Ideal for repairing old cast iron.

Technical Data

|

Typical Weld Metal Composition (%):

|

Fe:

<2 |

C:

1,2 |

Si:

<2 |

Mn:

<1 |

Ni:

>95 |

|

All Weld Metal Mechanical Properties:

|

Rm: >300 MPa

Hardness: ~ 180 HB

|

| Electrode polarity: |

Positive, Negative |

| Output Circuit Voltage (OCV): |

~ 40 V |

Hardfacing Electrodes

Rutile-basic coated electrode for surfacing of machines and

construction parts suffering from wear and tear, as well as of

tools made of low-alloyed and cast steels. Resistant to medium

abrasion, shock and pressure. Electrodes are easy to weld even

on small welding equipment with low open arc voltage. Soft flow,

almost no spatters, self releasing slag, nice aspect of the weld

beads, crack free deposit, machinable by grinding.

Applications

Hardfacing of moulds, scrapers, buckets and bucket teeth,

excavator parts, chisels, conveyer screws, track links, cutting

tools, crusher cones.

Advantages

- Universal all positions

- Good resistance to abrasion, shock and pressure

- Self releasing slag

- Machinable by grinding

Technical Data

|

Typical Weld Metal Composition (%):

|

Fe:

(base)

|

C:

1 |

Si:

0,5

|

Mn:

1,3

|

Cr:

4,5

|

|

Hardness:

|

~ 600 HB; 55-60 HRC Obtained in pour weld metal, 2-3

layers

|

|

Electrode polarity:

|

Negative |

|

Output Circuit Voltage (OCV)

|

~ 45 V |

Leave a Comment