GCE proFIT® PCM, Pipe Cutting Machine

The GCE proFIT® PCM is a universal, manually driven cutting

machine with a lightweight design for oxy-fuel applications,

ideal for cutting of pipes up to 100 mm of tube wall thickness.

Basic equipment contains a chain with the length for cutting

pipes with external diameter up to 400 mm. The chain is built by

the interlocking links which can be easily removed or added

based on particular tube diameter.

There is no electricity needed for operating the machine.

Therefore it is an ideal tool that can be used in each workshop

but also on-site.

Besides perpendicular cuts, the machine can be used for cutting

bevels with angle adjusted on the torch holder mechanism.

| Cutting capacity: |

up to 100 mm of tube wall thickness |

| Cutting speed: |

manually driven |

| Operation: |

forward and reverse manually operated |

| Oxygen inlet connection: |

G1/4“, up to 8 bar, hose min. DN8 |

| Fuel gas inlet connection: |

G3/8“LH, up to 1 bar, hose min. DN8 |

| Body dimensions: |

(400 × 500 × 600 ) ( W x L x H in mm) |

| Weight: |

15 kg |

| Chain links: |

Zn - coated, length 1300 mm, for tube diameter 1000

mm

|

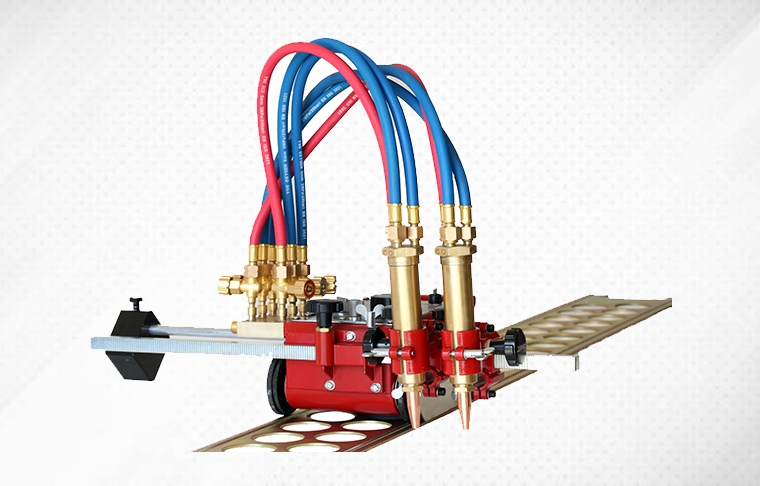

GCE Profit® SLM, Portable Straight Line Cutting Machine

GCE proFIT® SLM is a universal cutting machine with lightweight

design mainly for oxy-fuel cutting applications up to 150 mm

metal sheet thickness (up to 100 mm with two cutting torches).

It is a rugged but precise portable machine which has many

features and benefits. For example, it can be used for straight

cuts guided by the rail, manually-guided shape cuts, circular

cuts and Strip Cutting when using two torches. The cutting torch

can be fixed in a vertical position or angled for bevel cutting

of metal sheet edges. The machine is ideal for small workshops

or as an additional tool to a gantry machine. It can be used

indoor but also due to its flexibility it can be used outdoors

on the construction sites.

Features :

- Lightweight portable machine for one-hand manipulation.

- Easy installation and operation.

- Interlocking, 1,8 m long guide rail.

- All common fuel gases service.

-

Nozzle mixing (IC 30° cone) cutting torches or BIR+, an

injector cutting torch technology.

-

Basic one-torch configuration can be extended for two-torch

operation.

- Strip cutting and bevel cutting with two torches.

-

The precise drive system is ensuring constant cutting speed.

- Exact adjustment of the torch position.

-

High speed of motor drive enables the machine to be used also

for plasma cutting.

Technical Data

| Cutting capacity: |

up to 150 mm with one torch, up to 100 mm with two torches

|

| Cutting speed: |

50 - 1600 mm/min |

| Operation: |

forward and reverse with variable speed |

| Power supply: |

230V AC / 50 Hz |

| Oxygen inlet connection: |

G1/4“, up to 8 bar, hose min. DN8 |

| Fuel gas inlet connection: |

G3/8“LH, up to 1 bar, hose min. DN8 |

| Body dimensions: |

175 x 350 x 140 (W x L x H) |

| Weight: |

9,5 kg (with one torch configuration) |

| Rail: |

Zn-coated, 1,8 m |

Leave a Comment