Extensions for Low Flow

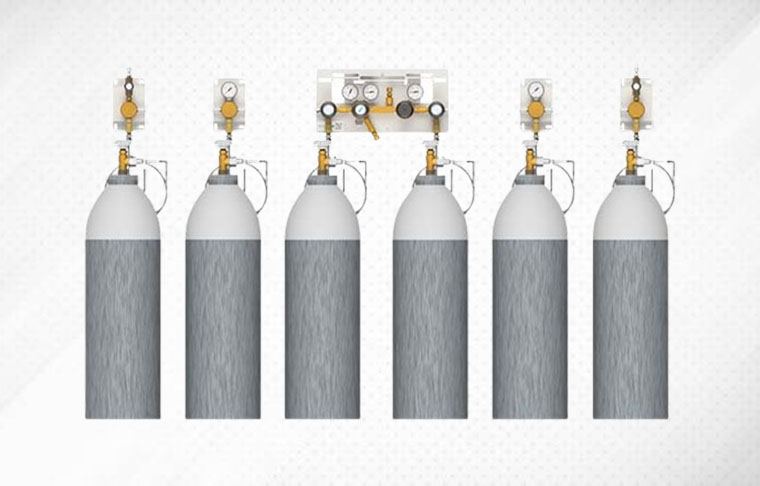

This extension header kits are used to increase number of high pressure inlet ports for manifolds in industrial gas supply systems for pure, inert, flammable, oxidising gases and gas mixtures.

Extension Header Kits were used to connect more than one gas cylinder on each side of the manifold. It can consist of diaphragm shut-off valve, tubing, inlet and outlet connection. Upon request, it can be equipped with check valves, gauges and vent valves, pressure transmitter and contact gauges. They can be delivered with up to 4 inlets. The Extension Header Kits are designed for safe handling of high purity gases.

Features :

- Up to four additional inlet ports are possible.

- Variable, configurable system.

- Extension Headers are optional equipped with manual actuated diaphragm valve, non return valve, gauge, contact gauge, pressure transmitter.

- Complete kits are available.

- Valves - developed, tested and produced in accordance with relevant sections of ISO 10297:2015 (including O2 ignition test for the main valve).

- Non Return valves -The special seat seal and the use of selected gas-wetted parts allow the use with Oxygen up to 300 bar.

- Electrostatic chargeability test.

- Fulfills requirements according to ISO 80079-36, IEC TS 60079-32-1 and German TRGS 727.

Specifications :

| Max. working pressure | 300 bar | |

| Working tempearture | - 20 °C to 60°C | |

| Nominal Flow Rate | 20 m³ / h | |

| Material: | ||

| Body | Brass (CW614N) | |

| Dimensions LxDxH (max): |

L030 (recommended for gas cylinders) |

L100 (recommended for gas bundles) |

| 1 inlet | 333 x 67 x 221 | 1033 x 67 x 221 |

| 2 inlets | 630 x 110 x 221 | 2033 x 110 x 221 |

| 3 inlets | 928 x 110 x 221 | 3033 x 110 x 221 |

| 4 inlets | 1226 x 110x 221 | 4033 x 110 x 221 |

| Specials: |

Check Valve – Type CV300 B Vent Valve – Type MVA530LG Check Valve + Vent Valve |

|

| Gauge Type: |

Bourdon Tube Inductiv Contact I1 Reed Contact R5 Pressure Transmitter Ex Pressure Transmitter Non-Ex |

|

Leave a Comment